ACO’s TramDrain manages stormwater problems for light railways

Light rail is an increasingly popular choice of transport in Australia. Not only is it a highly desirable means for travel for many Australians, but compared to traditional railways and buses, light rail travel is a quieter, smoother and often a more time and energy efficient ride for commuters. Additionally, as higher volumes of commuter traffic are catered for, the operational costs per customer are comparatively low.

In light of rapid economic growth and development in both urban and rural areas, these factors have recently driven strong interest from politicians and planners as they strive to make public transportation systems sustainable and effective.

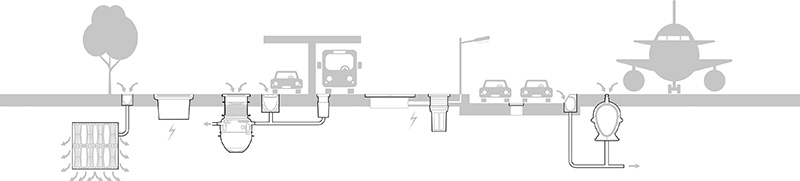

One key consideration of this new infrastructure is how it deals with rain. According to Railway Substructure.org, emphasis needs to be placed on how water is managed. A crucial element is that track installations do not add complication to the runoff and disposal of storm water. To be effective they must “intercept and redirect lateral storm water” (Railway Substructure, Rail Wiki, chapter 4.7.4.4.1.). This not only prolongs the life of the track but minimises the effects that water runoff can have on adjacent footpaths, roads and around building thresholds.

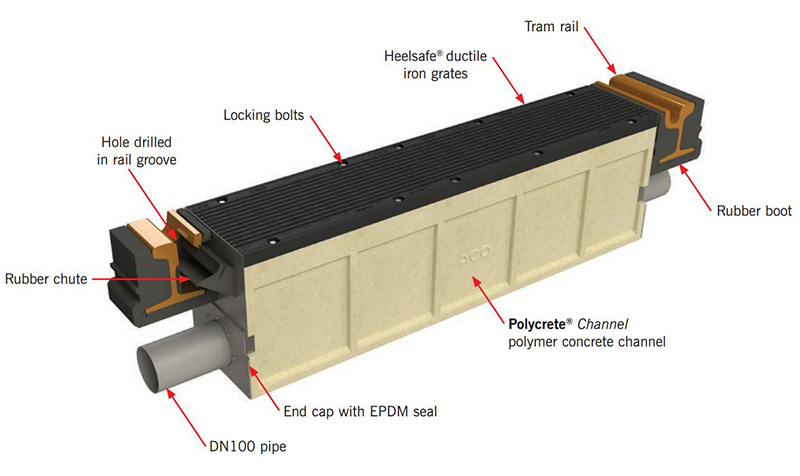

Linear drainage systems are essential solutions for the water management of track infrastructure. These vital systems must be specifically developed to suit grooved rail and track slabs in light rail environments. For instance, whilst the drain needs to be in contact with the rail for drainage, all metallic drain elements (grates, bolts etc…) must be isolated from stray currents in the tram rail. This is a key requirement for this type of drainage.

Track drains must also have the ability to be adapted for bespoke applications. A tram line’s drain performance is not the only criteria. Drain grates are in constant visual and physical contact with the urban environment and so grate aesthetics must also be taken into account. Additionally, not only are small slotted grates recommended to protect heels but these metallic elements must have a degree of slip resistance. Ease of access for maintenance is also critical if drains are to be kept functional for the design life of the project.

Track drains must also have the ability to be adapted for bespoke applications. A tram line’s drain performance is not the only criteria. Drain grates are in constant visual and physical contact with the urban environment and so grate aesthetics must also be taken into account. Additionally, not only are small slotted grates recommended to protect heels but these metallic elements must have a degree of slip resistance. Ease of access for maintenance is also critical if drains are to be kept functional for the design life of the project.

The competing requirements of hydraulics and constructability must also be evaluated in unison, this drives the need for intelligent drainage systems.

- Hydraulically, drains need to be large enough to cope with design storm water runoff volumes from both the pavement surface and the water collected by the rail. Each drainage system must have a sufficient number of connection outlets to the underlying storm water pipe network. These evacuation points can either be beneath the track or off to the side in an adjacent pavement. The size of the catchment area, the design rainfall intensity and the geometry of the track are key drivers to how the runoff, and how much runoff, is intercepted and collected by each drain.

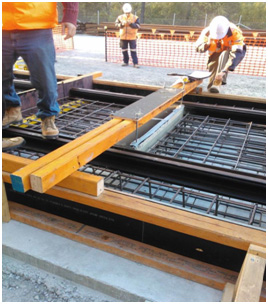

- From a constructability perspective, the relationship between the road and track surfaces must also be taken into account and in most cases; track slabs have a finite depth and therefore can only accommodate a compact drain. Engineers do not want the track slab to be unnecessarily deep nor do they want the drain to interfere with the main steel reinforcement layer.

Available in a choice of sizes, ACO’s TramDrain system can be adapted to any light rail track design. To remove water collected by the rail, the system comprises a rubber chute, which is flexible to suit various tram rail profiles. The rubber chute and end cap with EPDM seal is connected to the linear trench drain, yet isolates it from stray currents in the tram rail. The channel drain not only picks up water from the chute but also runoff from the track. Channels are manufactured from lightweight polymer concrete. Polymer concrete is an excellent material for drainage as it is a smooth material similar in roughness to PVC pipe, which enables fluids to flow at their optimum speeds.Utilising polymer concrete for drainage makes channels much easier to clean as it doesn’t support biological (plant life) or bacterial growth (mould).

TramDrain can be joined together across various tram track slab widths. The interconnecting channels discharge through a horizontal outlet or vertical outlet to the stormwater. All bolted grates are made from strong ductile iron, certified to AS 3996 Class D (210kN) pedestrian friendly (Heelsafe®) grates with 6.3mm slot width.

TramDrain 175A with Iron Slotted Grates was the solution specified by designers in Queensland’s new light rail network between the Gold Coast University Hospital at Southport and Broadbeach. ACO’s Technical Services Department provided designers with a bespoke solution that met both the hydraulic and structural requirements of the project.

Reflecting on the overseas success of ACO, it is clear that the company’s continuous investment in research and development and their ethos for innovation in water management supports the civil engineers challenge of coming up with novel ways to solve new problems. ACO’s track drainage solutions are not only adaptable to each states requirements for light rail, but can be customised to suit specific projects. This gives engineers full confidence that they have the best ‘surface to outlet’ drainage solution available. On-hand technical support from a Sydney-based advisory team can ensure support from the design phase of a project through to installation.

As the industry leader designing, manufacturing and supplying high performance systems for the rail sector, there is no doubt that ACO sees the careful control of naturally occurring environments, like rainwater runoff, as crucial to the safe and reliable operation of a public transport network.

To learn more about ACO’s track drainage solutions, call 1300 765 226, +61 2 4747 4000 or visit http://www.acoinfrastructure.com.au or email sales@acoaus.com.au.